Used components and equipment

We are offering a selection of used components and equipment that have been integral to our research and development in plasmalysis and its applications. These items, developed and utilized in various experimental and prototype settings, are now available for purchase. Below are some of the key items:

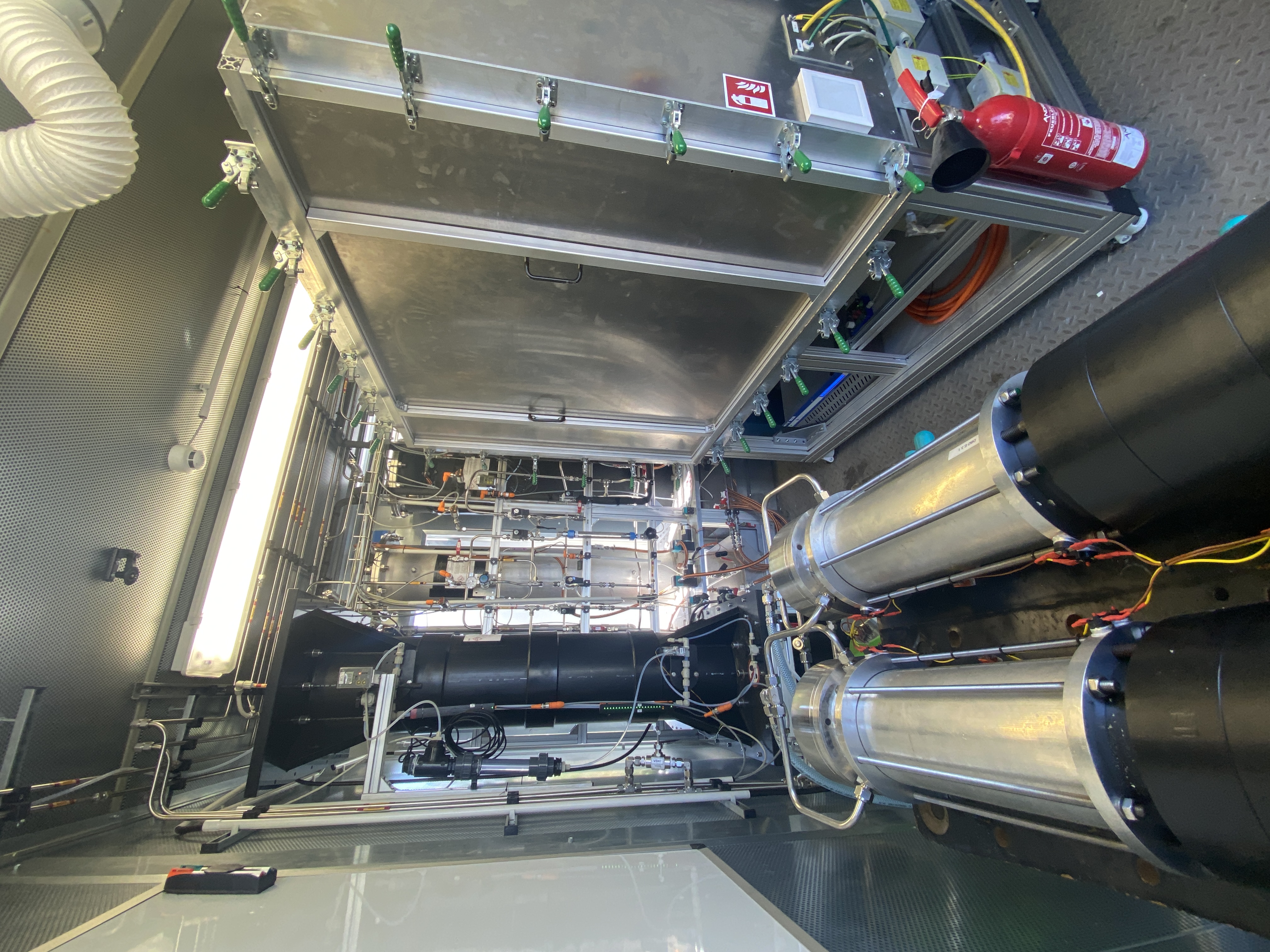

Gas Separation Container – Compact & Efficient Multi-Gas Handling Solution

This modular containerized unit is designed for the temporary storage and efficient separation of gas mixtures such as CO₂, H₂, N₂, and CH₄. It offers a flexible platform for research and industrial applications involving advanced gas processing.

Key Features:

- Gas Bundle Storage: For intermediate holding of mixed gases.

- High-Performance Membrane Unit: Equipped with two Evonik SEPURAN® membranes for selective gas separation.

- Compressor Stage 1 (up to 20 bar): Feeds gas mixtures into the membranes at optimal pressure.

- Integrated Gas Analysis: Monitors gas composition to ensure precise and consistent separation results.

- Compressor Stage 2 (up to 300 bar): Compresses the purified target gas (e.g., H₂) for downstream use or high-pressure storage.

- Siemens PLC Control System: Provides full automation, real-time process control, and safety monitoring.

This turnkey container system is ideal for pilot projects, research institutes, and decarbonization test environments requiring reliable, compact gas separation and compression.

- Designed for separation of CO₂, H₂, N₂, and CH₄ and mixed gas refueling

- Price: €95,000

Ammonia Plasma Cracker Container - Compact and containerized for easy deployment and operation

Our containerized ammonia plasmalysis system enables the safe, modular, and emission-free generation of green hydrogen (H₂) and nitrogen (N₂) from ammonia (NH₃). The process is based on a highly efficient Dielectric Barrier Discharge (DBD) plasma technology combined with heterogeneous catalysis.

Plasma System – Modular, Safe, and Scalable

At the heart of the container lies a robust metal enclosure with integrated safety and ventilation systems.

It includes mounting slots for up to 10 plasma reactor modules – currently, one module is installed.

Each reactor module features:

- A plasma chemo-catalytic reaction unit (multi-chamber design)

- Special electrodes generating high-voltage discharge

- Dielectric barrier for controlled plasma formation

- Recirculating water system for thermal stabilization and efficiency

- Catalyst pellets providing active surface for ammonia cracking

The entire reactor assembly is enclosed in a metal cube equipped with:

- Temperature and pressure monitoring

- Gas leak detection

- Active ventilation system

Ammonia Evaporation Unit

The pumped ammonia solution (up to 15 wt%) is collected in a 135-liter stainless steel tank where:

- It is heated to approx. 60 °C using a temperature-controlled heating rod (max. 70 °C)

- The pH level is monitored in real time

- A carrier gas flow (4.2 m³/h) of nitrogen or nitrogen/hydrogen is bubbled through the liquid via sintered metal diffusers

This drives off ammonia as a gas, yielding a vapor stream of: 4.2 m³/h N₂ / 5.2 m³/h NH₃ / at approx. 60 °C. The system is protected by safety valves triggered at 0.5 bar (1.5 bar(a)). In case of overpressure, the exhaust is neutralized via a sulfuric acid scrubber (BE04) and discharged through a roof-mounted vent.

Ammonia Supply Tank

A second 135-liter stainless steel tank stores a more concentrated ammonia solution (up to 25 wt%) for refilling BE02 as needed. BE01 is also: Monitored for fill level and overpressure and protected with the same safety valve and acid scrubbing system Equipped with a leak containment tray and chemical absorbent material beneath the tank

The combination of mechanical stability, functional modularity and integrated safety system makes this plasma system particularly suitable for university and industrial development environments.

- Designed for Compact and containerized for easy deployment and operation

- Price: €90,000

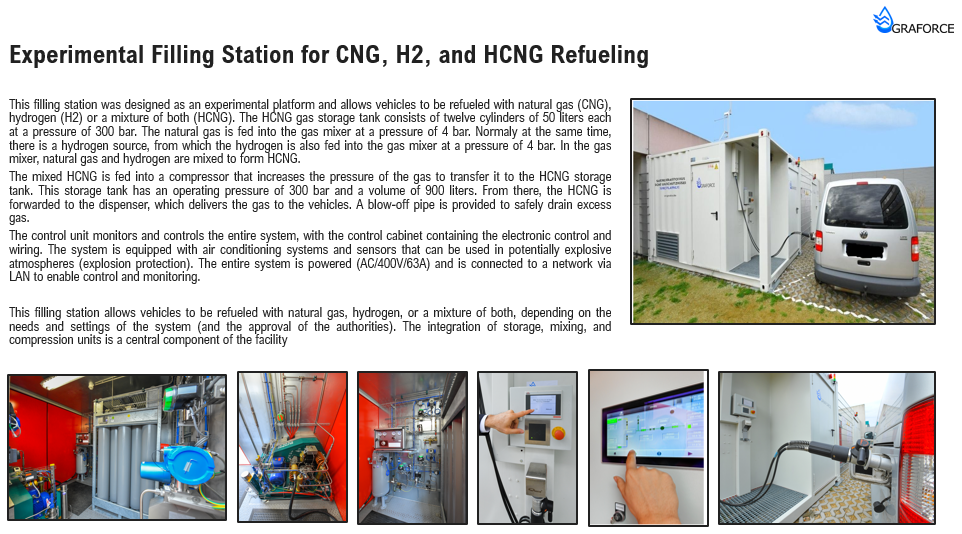

- Designed for natural gas, hydrogen, and mixed gas refueling

- Price: €98,900

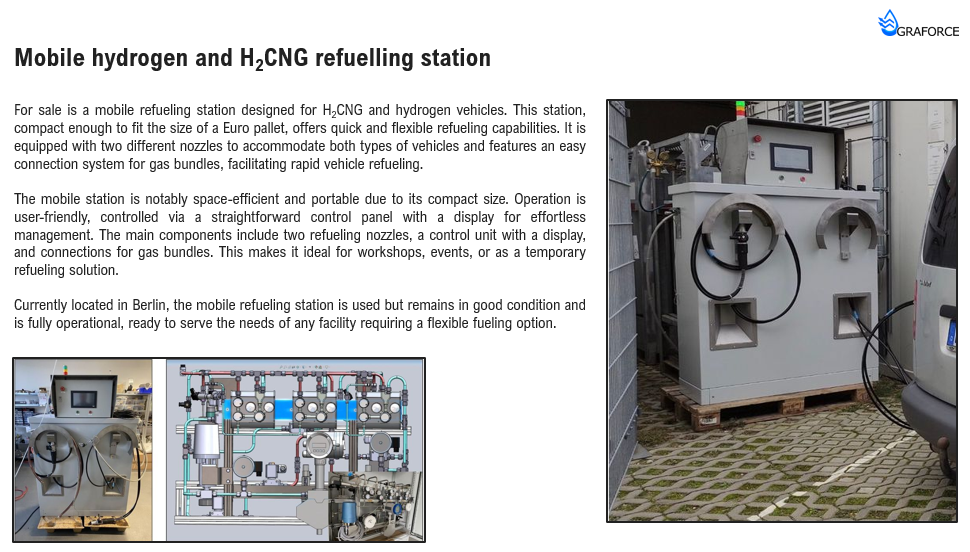

- Compact, portable refueling station for hydrogen vehicles

- Price: €9,900

-

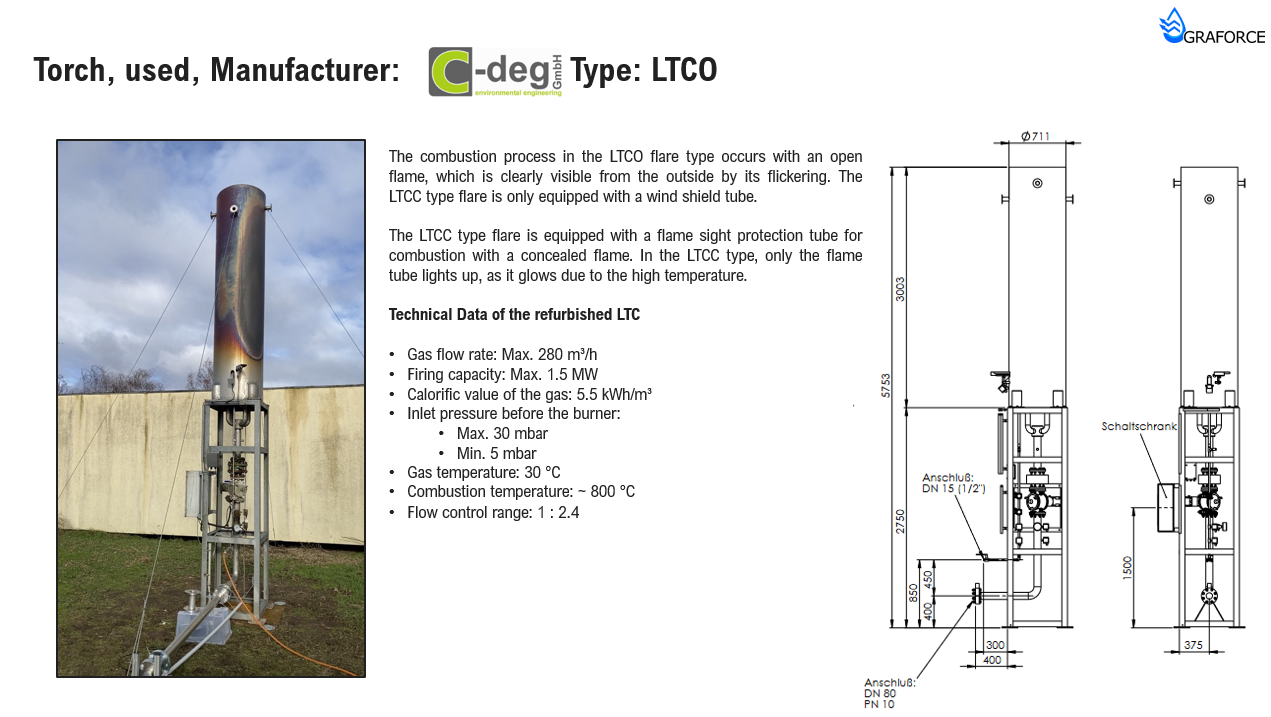

- Gas flow rate: Max. 280 m³/h

- Firing capacity: Max. 1.5 MW

- Price: €5,000

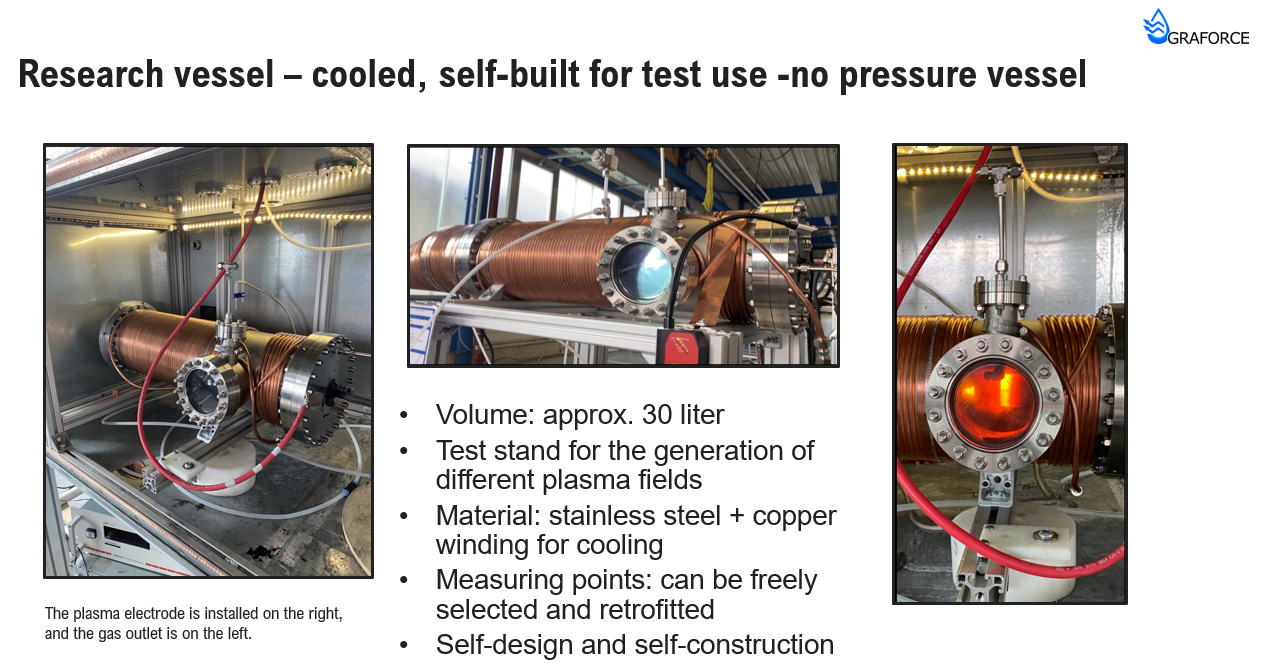

- Volume: Approx. 30 liters

- Material: Stainless steel and copper winding for cooling

- Price: €2,500

-

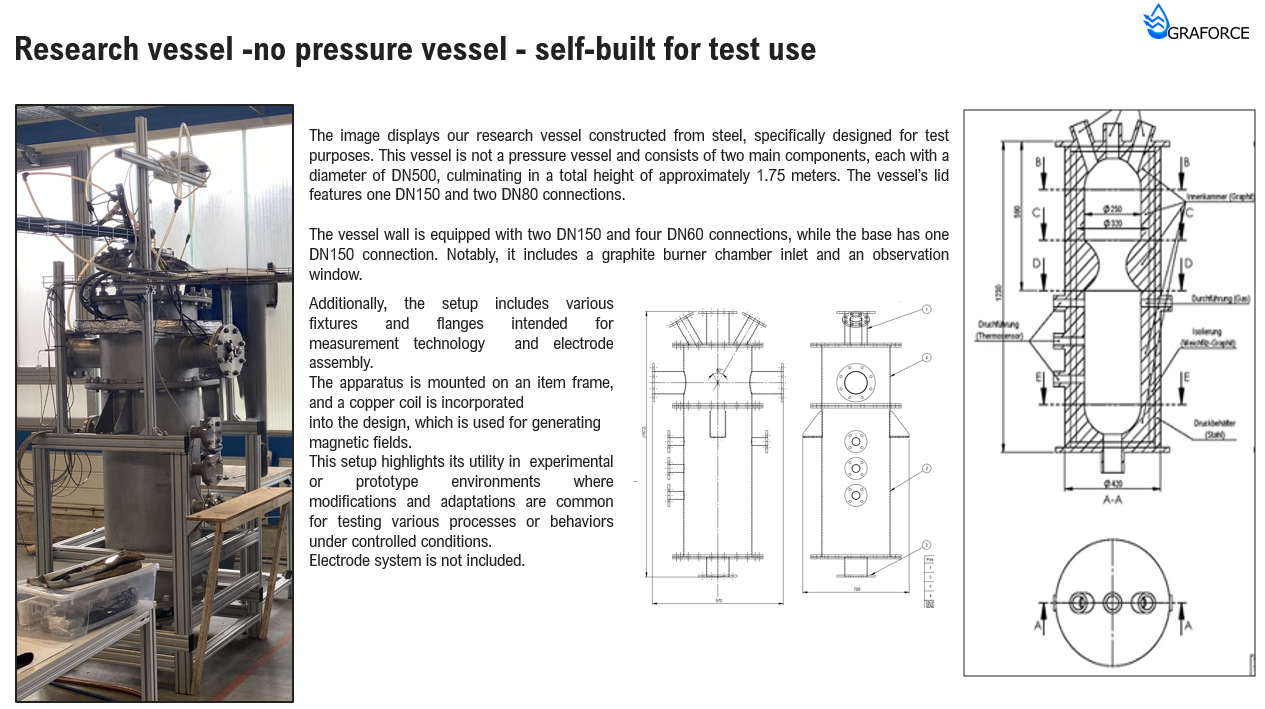

- Diameter: DN500, Height: Approx. 1.75 meters

- Includes graphite burner chamber inlet and observation window

- Price: €9,900

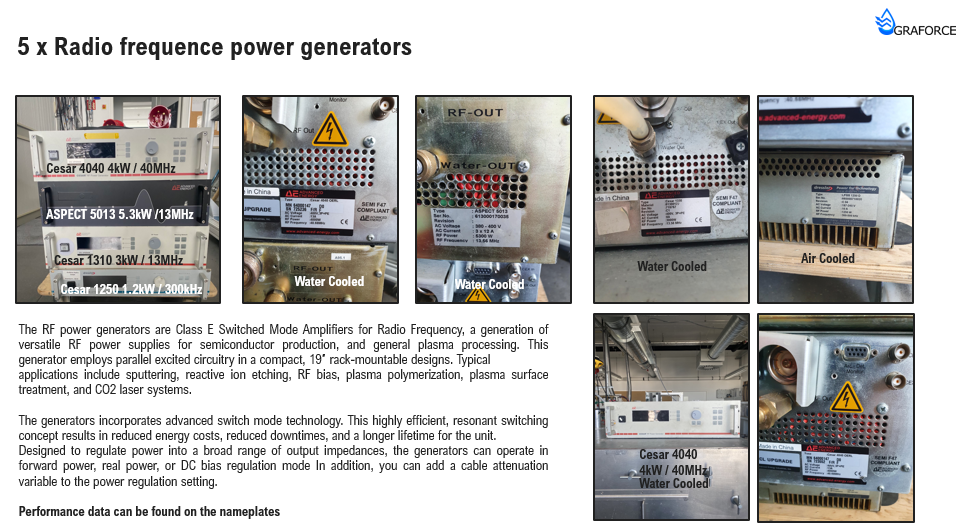

- Various models with power outputs from 1.2kW to 40kW

- Prices start at €3,000 per unit

- Price: € 8,000 per unit

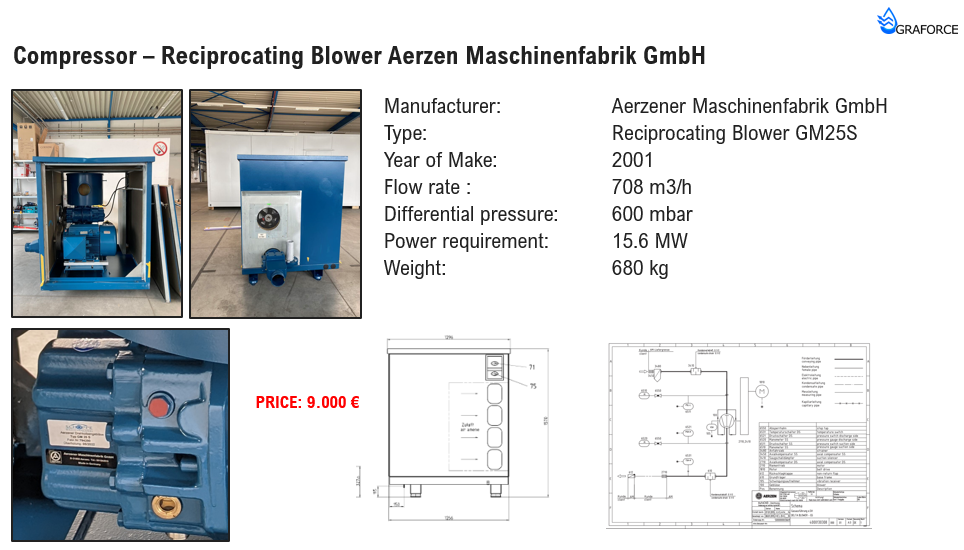

- Flow rate: 708 m³/h, Differential pressure: 600 mbar

- Price: €9,000

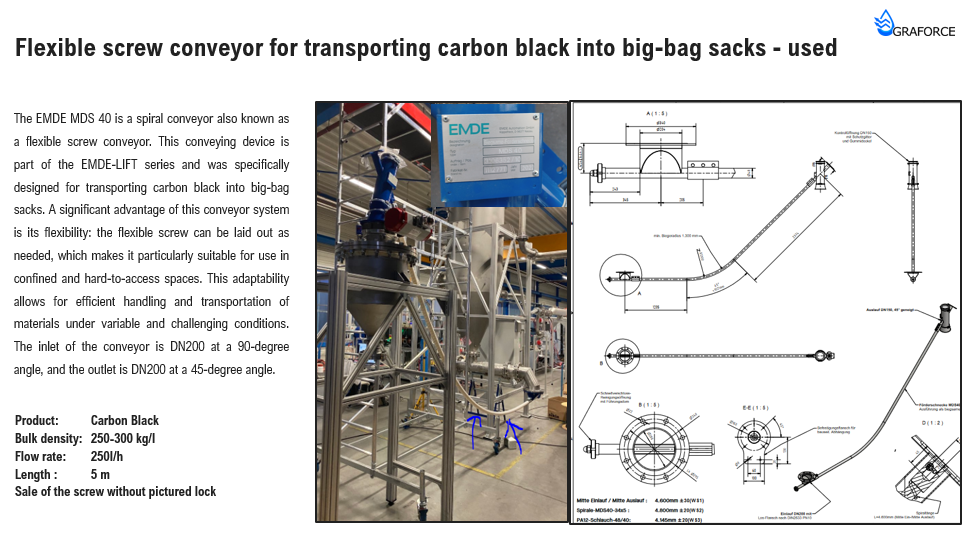

- Length: 5 meters, Flow rate: 250l/h

- Price: €2,000

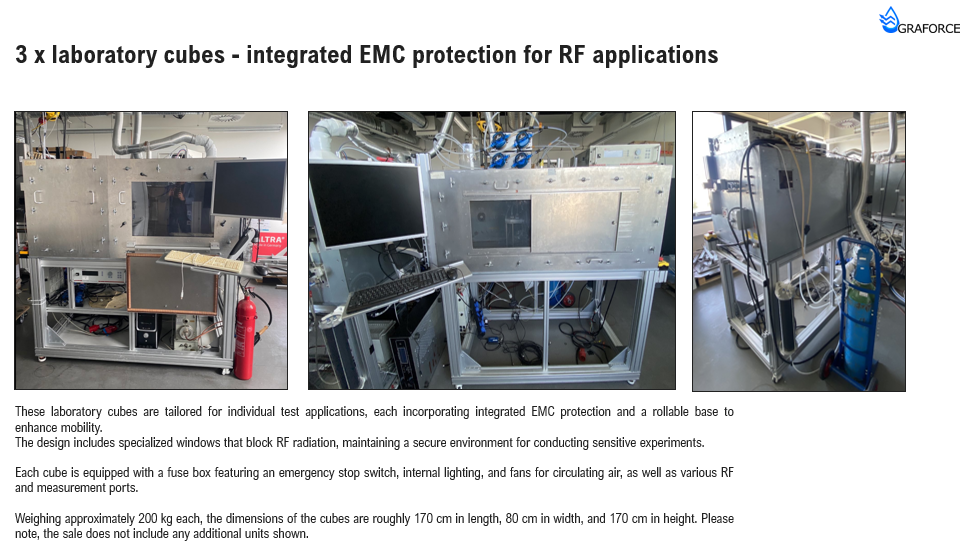

- Dimensions: 170 x 80 x 170 cm, Integrated EMC protection, Rollable base

- Price: €4,500 per unit

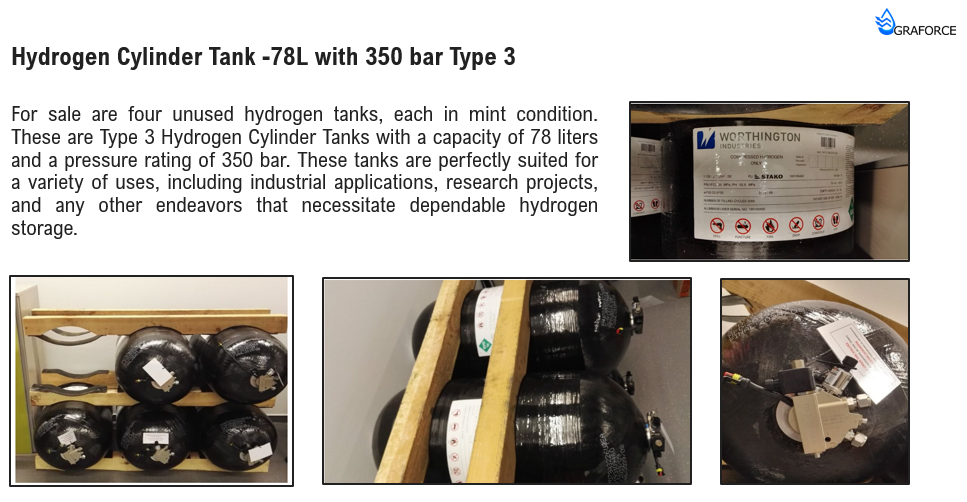

- Type 3 Hydrogen Cylinder Tanks

- Price: €2,000 per tank

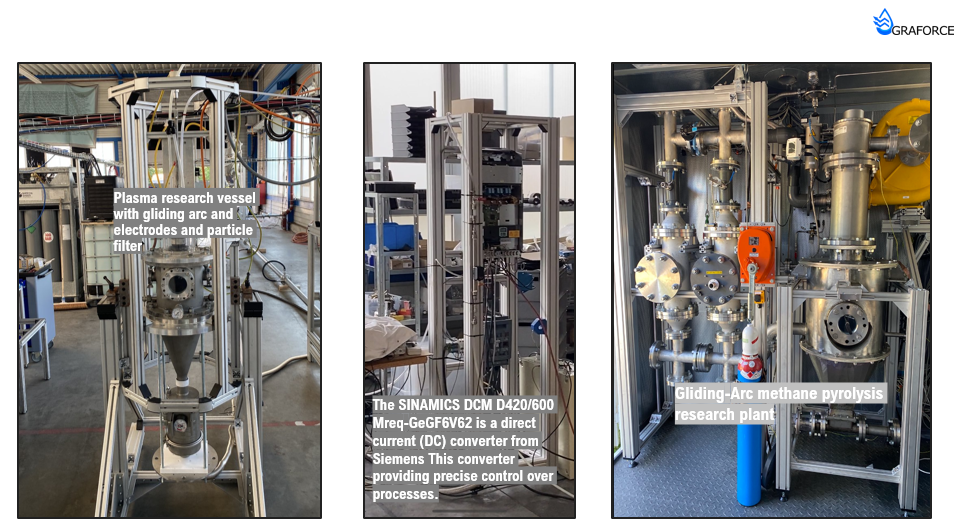

- Equipped with a particle filter, ideal for experimental setups

- Price: Available upon request

For detailed specifications and further information on each item, please contact us directly. These items are available for immediate purchase, and we are open to discussing offers.