Eigenschaften und Qualität unseres synthetischen Kohlenstoffs

Der feste Kohlenstoff, der bei der Methan-Plasma-Pyrolyse entsteht, ist weit mehr als ein Nebenprodukt: Er ist ein hochwertiges Funktionsmaterial mit vielfältigem Anwendungspotenzial. Hier zeigen wir, was ihn besonders macht – wissenschaftlich fundiert für Fachleute und verständlich erklärt für Anwender, Investoren und Partner.

Zur weiteren Erforschung und Entwicklung dieser Anwendungen arbeiten wir eng mit unserem Kooperationspartner, der RAG Austria AG im Bereich der kommerziellen Kohlenstoffnutzung zusammen. Gemeinsam untersuchen wir eine Vielzahl von Eigenschaften und Einsatzmöglichkeiten dieses festen Kohlenstoffs – von industriellen Anwendungen bis hin zu langfristigen Kohlenstoffspeicherlösungen.

Chemische Reinheit

Technisch:

- XRF-Analysen zeigen einen Kohlenstoffgehalt von 99,9 %

- Metallische Verunreinigungen liegen im ppm-Bereich (z.B. Fe ~0,007 %, Al <0,01 %)

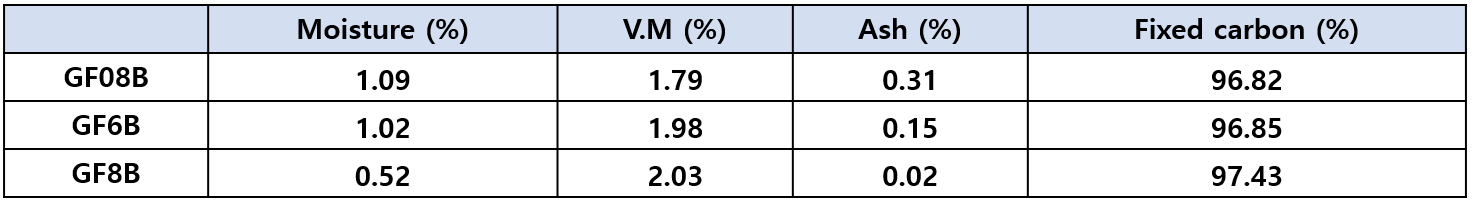

- Feuchtigkeitsgehalt: sehr gering (0,52 % – 1,09 %)

- Flüchtige Bestandteile: niedrig (1,79 % – 2,03 %)

- Aschegehalt: vernachlässigbar gering (nur 0,02 % – 0,31 %)

- Festkohlenstoffanteil: sehr hoch (96,82 % – 97,43 %)

Zusammenfassung: Unser Kohlenstoff besteht nahezu vollständig aus reinem Kohlenstoff. Feuchtigkeit, Asche und flüchtige Substanzen sind äußerst gering – ein Qualitätsmerkmal für leistungsstarke technische Anwendungen wie Batterien, Filter oder Verbundwerkstoffe.

Schüttdichte & Heizwert

Technisch:

- Klopfdichte der Plasmakohlenstoff-Proben (GF08B, GF6B, GF8B): 0,26 g/ml

- Referenz (N990 CB): 0.77 g/ml

- Heizwert: ~8,000 cal/g (Plasma carbon), 8,112 cal/g (N990 CB)

Zusammenfassung: Unser Kohlenstoff ist sehr locker und leicht - ein Vorteil für Anwendungen, bei denen geringes Gewicht und eine hohe Oberfläche gefragt sind. Gleichzeitig weist er einen hohen Hiezwert auf, der mit dem von Carbon Black vergleichbar ist.

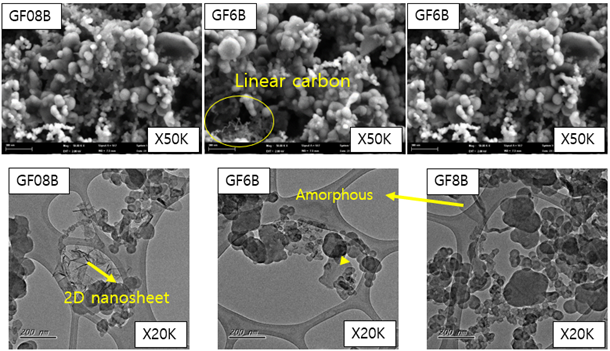

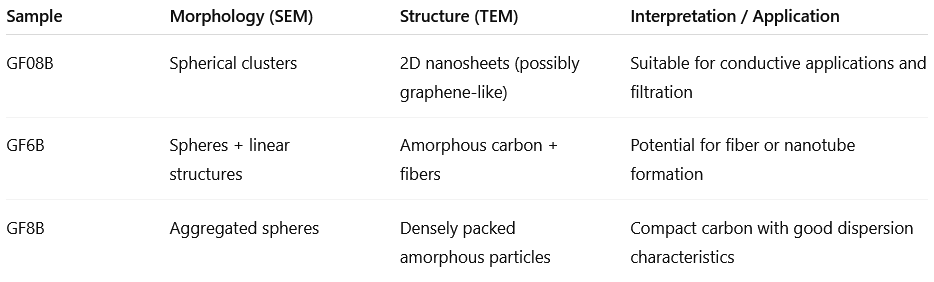

Struktur & Morphologie

Technisch:

- SEM- und TEM-Aufnahmen zeigen amorphe Cluster, 2D-Nanoschichten und faserartige Strukturen

- XRD-Analyse: Breite, schwache (002) Peaks bestätigen die amorphe Struktur

Zusammenfassung: Das gleichzeitige Vorkommen von amorphem, faserartigem und nanoschichtartigem Kohlenstoff aus einem einzigen Prozess (Plasma-Pyrolyse) ist außergewöhnlich und ermöglicht:

- Einsatz in Batterien und Superkondensatoren (durch 2D-Strukturen)

- Anwendung in Filtern oder als Trägermaterial für Katalysatoren (dank großer Oberfläche)

- Potenzial für leitfähige Verbundwerkstoffe (durch die Mischung aus Fasern und amorphem Kohlenstoff, z. B. für Elektroden)

Porenstruktur & Oberfläche

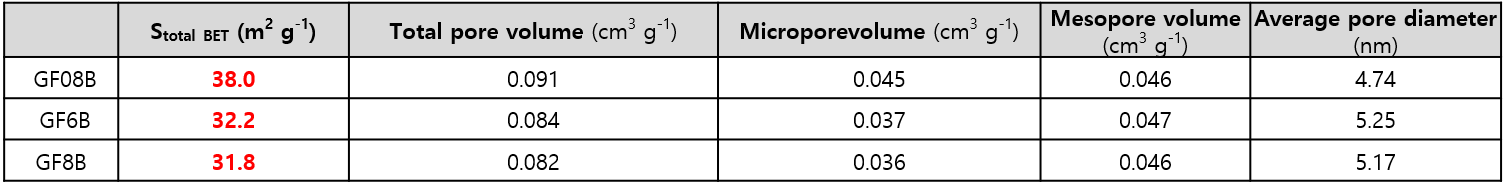

Technisch:

- BET-Oberfläche: 32 m²/g –38 m²/g

- Porenverteilung: Kombination aus Mikro- und Mesoporen, durchschnittlich ~5 nm

- Isotherm Typ V: geringe Stickstoffaffinität, keine Hysterese

Der Kohlenstoff weist eine feine, gleichmäßige Porenstruktur auf (bestehend aus Mikro- und Mesoporen), was ihn ideal für Anwendungen wie Batteriematerialien oder Filtersysteme macht.

Seine spezifische Oberfläche liegt bei etwa 30 m²/g –38 m²/g – deutlich höher als bei herkömmlichem industriellen Ruß, und das ohne kostenintensive Aktivierungsverfahren.

Die Poren sind funktionell zugänglich, aber nicht übermäßig entwickelt, wodurch der Kohlenstoff leicht dosierbar und äußerst vielseitig einsetzbar ist – z. B. in Kunststoffen, Gummi, Farben oder als Katalysatorträger.

Zusammenfassung: Materialien mit ausgewogenen Porenstrukturen sind in Zukunftsmärkten stark gefragt – etwa in der Energiespeicherung, bei Leichtbau-Verbundstoffen oder in CO₂-Filterlösungen. Im Gegensatz zu Aktivkohle bindet unser Kohlenstoff Gase nicht übermäßig stark, was ihn leichter handhabbar und kosteneffizienter in der Verarbeitung macht. Wir verbinden industrielle Relevanz mit Nachhaltigkeit: Unser fester Kohlenstoff ist ein wertvoller Rohstoff – kein Abfallprodukt.

Elektrische Leitfähigkeit

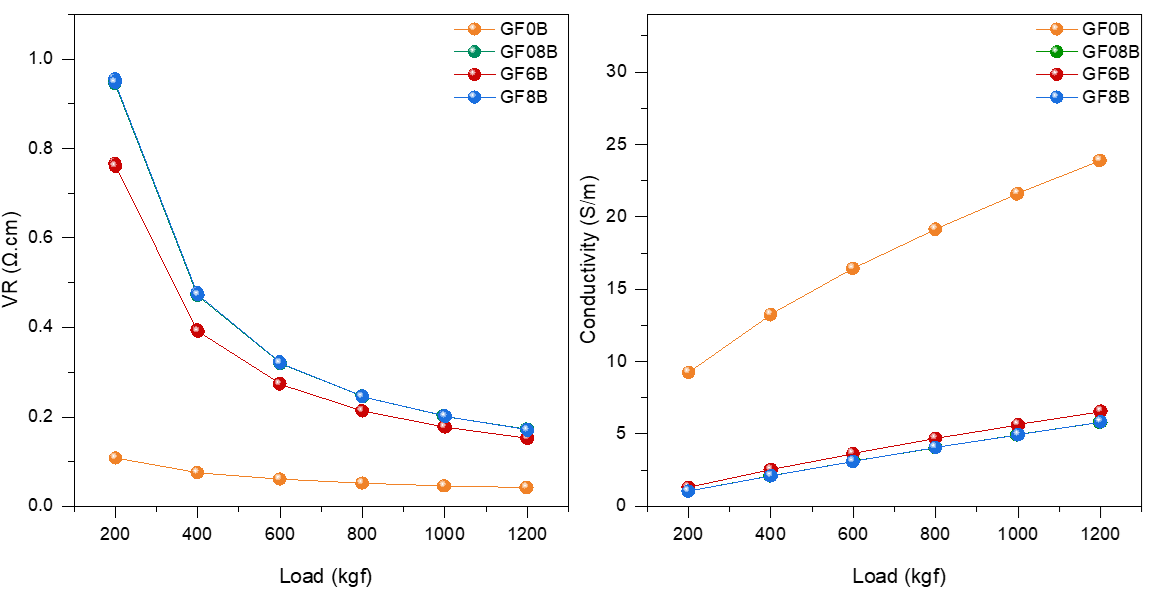

Technisch:

- Leitfähigkeit: 4 S/m –6 S/m bei 1.200 kgf Druck - je stärker der Kohlenstoff verdichtet wird, desto besser leitet er Strom

- Widerstand sinkt mit zunehmender Kompression → gute Kontaktleitfähigkeit

Zusammenfassung: Der durch Methan-Plasma-Pyrolyse erzeugte Kohlenstoff ist elektrisch leitfähig, insbesondere bei Verdichtung – ideal für Anwendungen wie:

- Leitfähige Kunststoffe (z. B. ESD-Schutz, antistatische Gehäuse)

- Gummimischungen für Sensoren

- Elektrodentechnologien

Auch wenn er nicht die Leitfähigkeit hochgradig graphitierter Kohlenstoffe erreicht, bietet er eine hervorragende Balance aus Leitfähigkeit, Struktur und Nachhaltigkeit – und das bei kosteneffizienter Herstellung im industriellen Maßstab.

Thermische Stabilität

Technisch:

- TGA in N2: stable up to >800°C, max. weight loss 2.3% TGA in N₂: stabil bis über 800 °C, max. Massenverlust 2,3 %

- In Luft: Verbrennung beginnt bei ca. 650 °C

Zusammenfassung: Der Kohlenstoff bleibt auch bei hohen Temperaturen stabil. Ohne Sauerstoff zersetzt er sich kaum – unter Luft kann er als Brennstoff oder thermisch verarbeitet werden.

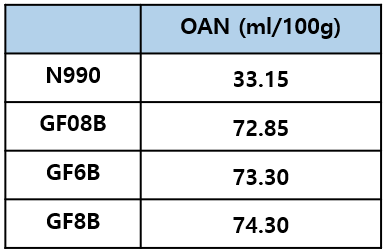

Oil Absorption Number (OAN)

Der Kohlenstoff der Graforce weist eine Oil Absorption Number (OAN) von etwa 72 – 74 ml/100 g auf – etwa doppelt so hoch wie die eines N990-Ruß-Referenzmaterials (~33 ml). Ein höherer OAN-Wert deutet auf eine stärker strukturierte, aggregatreiche Kohlenstoffform hin, die mehr Flüssigkeit aufnehmen kann. In der Praxis bedeutet das: Unser Kohlenstoff lässt sich hervorragend mit Ölen, Polymeren und Bindemitteln vermischen – für eine gleichmäßige Verteilung in Gummimischungen, Kunststoffen, Druckfarben oder Betonzusätzen.

Technisch:

- OAN-Werte: 72 – 74 ml/100 g (Referenz N990: 33 ml) deutet auf eine hohe Struktur und sehr gute Dispergierbarkeit hin

Zusammenfassung: Unser Kohlenstoff nimmt Öle und Bindemittel außergewöhnlich gut auf. Dies ist ein klares Zeichen für exzellente Mischbarkeit in Anwendungen wie Gummi, Farben oder Kunststoffen.carbon absorbs oils and binders extremely well.

Vergleich mit konventionellem Kohlenstoff (z.B. N990)

Technisch:

- Im Vergleich zu N990 CB: etwa doppelt so hoher OAN-Wert, Gleiche oder bessere thermische Stabilität, feinere Porenstruktur

- Übertrifft herkömmlichen Furnace Black in Struktur- und Dispergiereigenschaften

Zusammenfassung: Im Vergleich zu konventionellem industriellem Ruß ist unser Kohlenstoff feiner, strukturreicher und leistungsfähiger – mit dem zusätzlichen Vorteil eines deutlich geringeren CO₂-Fußabdrucks.

Nachhaltigkeit & CO₂ - Vorteile

Technisch:

- CO₂-Einsparung gegenüber fossilen Kohlenstoffquellen: bis zu 5,5 Tonnen CO₂ pro Tonne Kohlenstoff (im Vergleich zu petrolkoks-basiertem Ruß)

- Kein Vor- oder Nachbehandlungsprozess erforderlich, geringer Energiebedarf dank Plasmatechnologie

Zusammenfassung: Unser Kohlenstoff ist nicht nur technisch leistungsstark, sondern auch klimapositiv: Jede produzierte Tonne vermeidet CO₂ im Vergleich zu konventionellen Alternativen – ein echter Beitrag zu nachhaltiger Industrie.

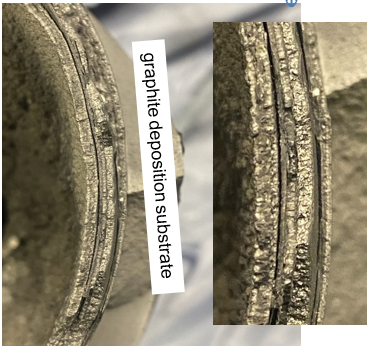

Bewertung der Partikelstabilität von Graforce-Kohlenstoff für Chlorierungsprozesse

Zur Beurteilung der Eignung unseres festen Kohlenstoffs für thermochemische Chlorierungsverfahren wurde ein Test zur mechanischen Festigkeit und Abriebfestigkeit durchgeführt. Ziel war es, festzustellen, ob das Material während der Handhabung seine strukturelle Integrität behält und ob die resultierende Partikelgrößenverteilung den typischen Prozessanforderungen entspricht.

Zentrale Ergebnisse:

- Die getesteten Kohlenstoffproben zeigten eine Partikelgrößenverteilung unter 500 µm, vergleichbar mit mehreren industriellen Referenzmaterialien.

- Mit einem Feinkornanteil von ca. 3 % – 4 % liegt das Material im branchenüblichen Bereich und weist keinen übermäßigen Abrieb bei der Aufbereitung auf.

- Zum Vergleich: Andere getestete Kohlenstoffqualitäten zeigten höhere Feinkornanteile bis zu 7 %, was die Verweilzeit im Reaktor verringern und die Umwandlungseffizienz beeinträchtigen kann.

- Der Anteil an Ultrafeinpartikeln (<50 µm) war bei allen Proben niedrig – ein positives Indiz für Reaktorstabilität und Prozesssicherheit.

Testbedingungen (Auszug):

- Der Kohlenstoff wurde mit einem Masseanteil von 18 % bezogen auf die Trockensubstanz eingesetzt.

- Die Ergebnisse wurden mit physikalisch aufbereiteten industriellen Referenzkohlenstoffen verglichen, darunter hochwertige kalzinierte Materialien.

Zusammenfassung: In dieser ersten Untersuchung zeigte unser Kohlenstoff eine ausreichende mechanische Stabilität und ein günstiges Feinkornprofil. Die Ergebnisse sprechen dafür, dass das Material für den Einsatz in Chlorierungsprozessen geeignet ist – insbesondere im Hinblick auf Prozesskompatibilität und betriebliche Stabilität.

Pelletierter Kohlenstoff – Optimiert für industrielle Handhabung und Leistungsfähigkeit

Neben seiner chemischen Reinheit und elektrischen Leitfähigkeit überzeugt unser Kohlenstoff auch durch seine physikalische Anpassungsfähigkeit. Für viele industrielle Anwendungen – etwa in der Metallurgie, Chemie, Energie- oder Umwelttechnik – ist nicht nur die Zusammensetzung, sondern auch die Verarbeitungsform des Materials entscheidend. Aus diesem Grund haben wir erfolgreich mehrere Pelletierungsverfahren für unseren Plasmapyrolyse-Kohlenstoff entwickelt.

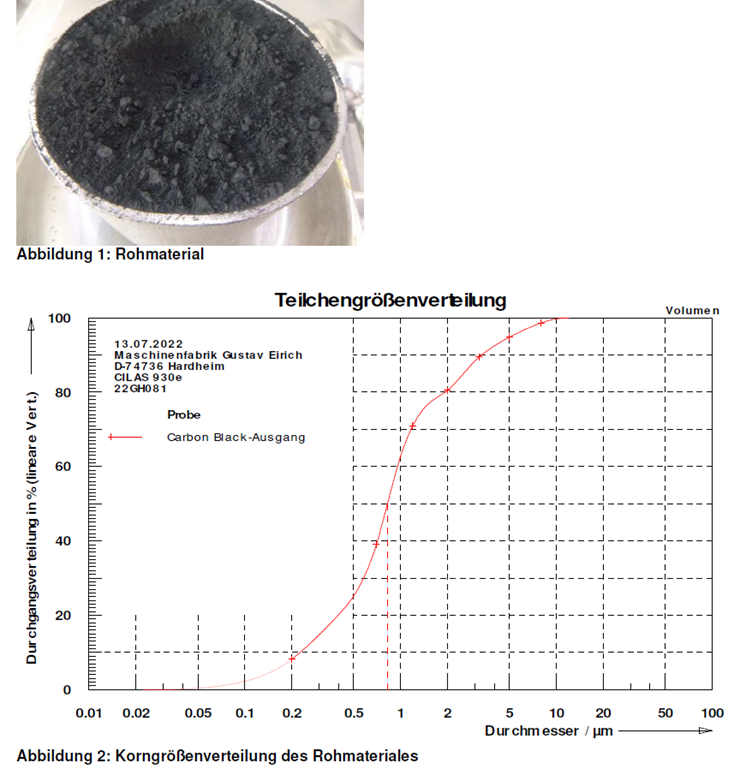

Ausgangspunkt: Fein verteiltes Pulver

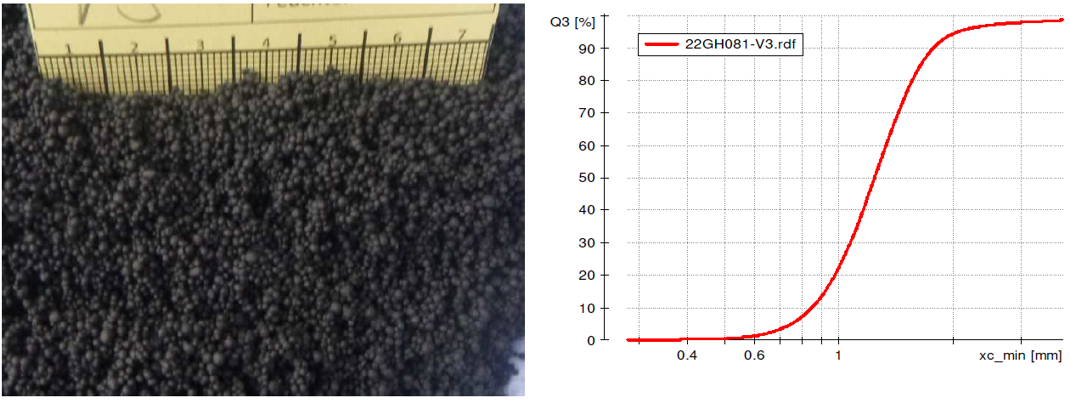

Das Ausgangsmaterial wird als feines, freifließendes Pulver geliefert, mit einer Partikelgrößenverteilung hauptsächlich zwischen 0,5 µm und 10 µm (siehe Abbildungen 1 und 2). Diese feine Struktur bietet eine sehr hohe spezifische Oberfläche – ideal für Adsorptions- oder Katalyseanwendungen. Die Pulverform stellt jedoch bei der Verarbeitung im industriellen Maßstab Herausforderungen dar, da sie zu Staubbildung, ungleichmäßiger Dosierung und einer verkürzten Verweilzeit im Reaktor führen kann.

Trockene mechanische Pelletierung (ohne Zusatzstoffe)

Durch rein mechanische Verdichtung – ohne chemische Bindemittel – wurden Pellets mit Durchmessern von etwa 0,8 mm –1,2 mm hergestellt. Eine Partikelgrößenanalyse bestätigt eine enge Korngrößenverteilung im Millimeterbereich, ideal für Schüttgutverarbeitung und gleichmäßige Reaktorleistung.

✔ Keine Bindemittel – 100% reiner Kohlenstoff

✔ Minimale Feinanteilbildung

✔ Hohe thermische und mechanische Stabilität

✔ Einfach zu lagern, zu transportieren und zu dosieren

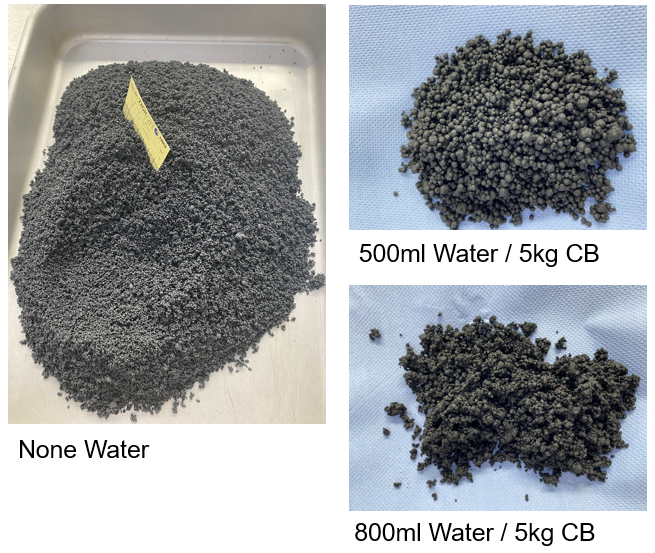

Wasserunterstützte Pelletierung

Zur Verbesserung der Granulatbildung haben wir auch eine wasserbasierte Pelletierung getestet. Durch Anpassung des Wassergehalts konnten wir die Konsistenz der Pellets beeinflussen, ohne Fremdstoffe einzubringen.

| Water Addition | Pelletization Result |

|---|---|

| 0 ml / 5 kg carbon | Powder remains free-flowing, no pellet formation |

| 500 ml / 5 kg carbon | Uniform pellets, good mechanical integrity |

| 800 ml / 5 kg carbon | Softer agglomerates, cohesive but less rigid |

Je nach Prozessanforderungen können Pelletfestigkeit und Feuchte entsprechend angepasst werden – von rieselfähig bis formstabil.

Vorteile für industrielle Prozesse

- Staubfreie Handhabung in Logistik und Betrieb

- Verbessertes Dosierverhalten in Reaktoren und kontinuierlichen Systemen

- Stabile Verweilzeiten, entscheidend für Chlorierung und Pyrolyse

- Skalierbar und bindemittelfrei – erhält die Kohlenstoffreinheit

- Anpassbare Pelletfestigkeit durch Feuchteregulierung